IPL Analyzer

New designed device intended for synchronous

and continuous 12-bit sampling and digitizing of 4+1 input signals. Data from all input channels are continuously stored to

computer hard disc. Analog input circuits are derived from XEDO system. Communication with PC and data transfer is realized

via USB 2.0 interface. All data are stored to hard disc with speed cca 16 MB/sec, i.e. cca 56 Gbytes per hour. Total

measurement time is limited by disk capacity only. Hard disk interface must be able to work continuously with the same

speed as a data transfer (e-SATA port).

New designed device intended for synchronous

and continuous 12-bit sampling and digitizing of 4+1 input signals. Data from all input channels are continuously stored to

computer hard disc. Analog input circuits are derived from XEDO system. Communication with PC and data transfer is realized

via USB 2.0 interface. All data are stored to hard disc with speed cca 16 MB/sec, i.e. cca 56 Gbytes per hour. Total

measurement time is limited by disk capacity only. Hard disk interface must be able to work continuously with the same

speed as a data transfer (e-SATA port).

| Technical parameters |

||

| Number of Channels: | 4 channels for acoustic emission signal 1 channel for auxiliary record |

|

| Input Amplifiers Gain - AE channels: | Software-settable in 0dB až +80 dB range | |

| Input Impedance - AE channels: | 820 Ohms | |

| Input Voltage in Auxiliary Channel: | -30V to +30V, 10-bit A/D converter | |

| Input Impedance - Auxiliary Channel: | 200 kOhms | |

| Sampling Speed - all channels: | 2 MSamples/sec | |

| Frequency Range: | 50 kHz to 600 kHz (4 AE channels) DC to 2 kHz (auxiliary channel) |

|

| Dimensions (h x w x d): | 120 x 175 x 270 milimeters | |

| Power: | 100-240VAC, 50-60 Hz, max. 25W or 12VDC/1A from external adapter |

|

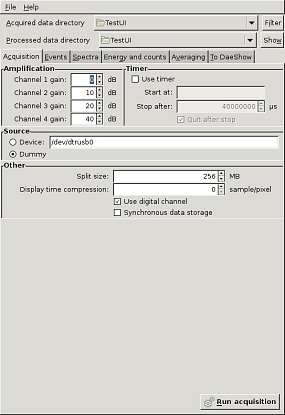

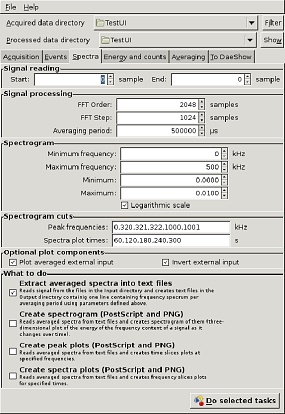

All input signals voltage can be watched on computer display during the data acquisition. Data storing to the computer hard disk during watching can be stopped for gain setting and functionality testing. Software Dakel-UI runs under Linux OS and provides stored data processing. There are these possibilities for data processing:

External preamplifiers between sensors and IPL inputs can be powered from IPL inputs via signal coaxial cables. Preamplifiers located close to sensors (or integrated in sensors) improve interference immunity and reduce the noise.

Continuously sampled and stored acoustic emission signal alows use of modern mathematic-statistic methods oriented for emision sources identification. Evaluation of signal features can be many times repeated with diferent parameters. Aditional measuring and data acquisition is not necessary. That is the main diference between IPL and conventional instruments.

Software Dakel-UI provides communication PC with IPL, data storing and

subsequent evaluation. Some program windows are demonstrated: data

acquisition - left, spectrogram generation - right:

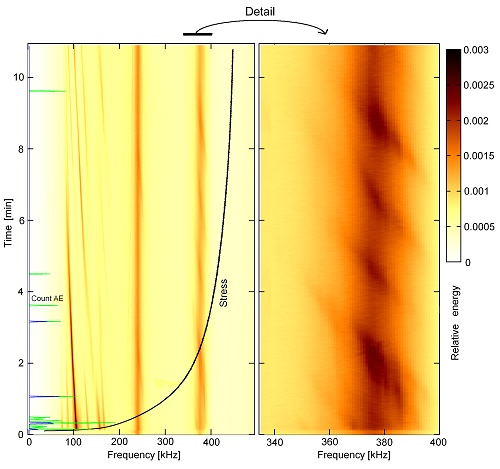

Sample of three-dimensional spectrogram, generated after tensile test of the

99.99% pure aluminium:

X-axis (horizontal): frequency, Y-axis (vertical): time, Z-axis (pixel color):

signal amplitude - energy. The black line in left part of picture demonstrates

time-dependance of stress (auxiliary channel record). Green peaks full left

demonstrate time dependance of counts (amplitude overshoot of prdefined threshold).

FP7-ALAMSA

FP7-ALAMSA